In this Executive Update we share new infographics on asphalt benefits, tell what we learned at national meetings, and explain how air void regression improves asphalt roads.

- Infographics Tell the Drivability Story

- Association Execs Share Best Practices

- NAPA Midyear Meeting

- Building Better Pavements: Air Void Regression

- Coming Soon: WAPA Design Guide; Annual Conference

|

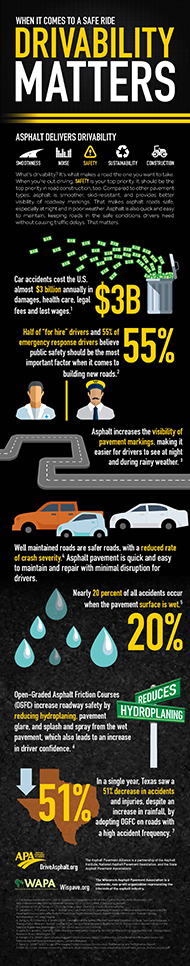

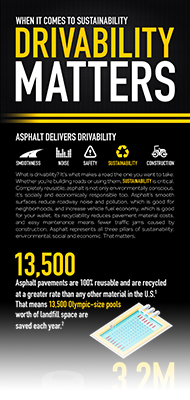

WAPA’s marketing page has grown yet again with the addition of five infographics developed by the Asphalt Pavement Alliance. Each of the web-friendly images tells a compelling story about five areas where asphalt makes a difference: safety, noise, smoothness, roadway construction, and sustainability. These are the prime areas of concern for drivers when it comes to roads, and the infographics use research-based facts and statistics to spell out the benefits in a clear, concise, and easy-to-follow way. Together with the videos and ads on WAPA’s marketing page, the infographics are a useful tool to definitively answer the question: Why is asphalt the safe pavement? (And the sustainable one? And the smooth ride?) We invite you to explore these infographics and share them with your colleagues, customers, and anyone else who wants to learn more about what drivers want and why asphalt is the pavement of choice. Click any of the images here to expand the complete infographic to full size. |

||||

Earlier this month I had the chance to sit down with my fellow SAPA execs in Des Moines, Iowa. This was an excellent opportunity for us to discuss the wide range of issues that affect the asphalt pavement industry as experienced from our respective states.

Round tables and one-on-one discussions touched on everything from technical innovations, pilot projects and specification changes to legislation, funding, and long-term industry shifts.

The candid exchanges with other execs are tremendously helpful. It’s useful to know that we face common challenges, and I always learn new approaches to overcome obstacles. I have also picked up some best practices about running an effective association and shared some success stories from Wisconsin. Some of WAPA’s outreach efforts and annual conference activities are a result of hearing what has worked well for other SAPAs.

I look forward to continued, active involvement with the SAPAs as a way to better serve WAPA members and to work more effectively with our partners back home.

- Brandon Strand’s NAPA Committees

Pavement Economics

Legislative

Communications

Political Action

Go-To-Market Task Group - Deb Schwerman’s NAPA Committees

Asphalt Research & Technology

Engineering Advisory Council

Sustainability

Environmental

Health and Safety

This committee engagement lets us keep track of and provide input on NAPA’s agenda for research and advocacy and help make sure that NAPA is working in the best interest of Wisconsin’s asphalt industry.

Bursts of knowledge from “micro sessions”

The micro sessions covered the wide range of work that NAPA addresses. Noteworthy sessions included:

- “Not So FAST―We Still Need a Revenue Increase for Highways!” by Ed Mortimer, U.S. Chamber of Commerce, and Greg Cohen, U.S. Highway Users Alliance

- “Improving Performance What Can You Do NOW!” by Randy West, NCAT

- “Green Rating Systems: Today’s Credit and Tomorrow’s Greener Vision” by Nicole Jackson and Jeralee Anderson, Greenroads

- “Complying with OSHA’s New Silica Rule” by Chris Trahan, Center for Construction Research and Training

- “What’s New with PaveXpress” by George White, Pavia System

Congratulations Payne & Dolan

During the midyear meeting, NAPA also recognized WAPA member Payne & Dolan with two major awards. We extend our sincerest congratulation for the well-deserved national honor.

|

Asphalt Operations Safety Innovations Award for most innovative safety practices Winner

|

Ecological Award for safe and responsible environmental practices Winner

|

One technical advancement that’s creating a lot of buzz in Wisconsin is called air void regression. Engineering Director Deb Schwerman provided the details below on the technique that aims to improve asphalt pavements.

Improving pavement performance in Wisconsin

One of our goals in Wisconsin is to improve pavement durability, and we know that adding liquid asphalt cement (to a limit) improves the performance of asphalt mixes. The big question has been: How do we add more asphalt cement most effectively?

Following techniques used in Michigan, Wisconsin developed a method to get more effective adhesive into the mix. It’s called “air void regression,” and the idea is to keep the design methods the same; then determine how much additional virgin asphalt cement is needed to achieve 3.0 percent air voids instead of 4.0 percent. The 3.0 percent target is associated with a more durable asphalt; it is also associated with denser asphalt mix (especially for low- and medium-traffic applications).

Achieving the lower air void target takes work. It requires a narrower tolerance band in production, with plants dialed-in to create a mix that matches what was designed in the lab—and that remains consistent day after day.

All expectations are that the end result will be well worth it, and right now the Wisconsin Highway Research Program has research underway to fully document the outcomes of air void regression.

(Image courtesy of Mathy Construction)

Building on a federal project

Wisconsin is involved in a national effort in this area as well. In March, FHWA’s Office of Asset Management, Pavements & Construction announced that WisDOT was one of 10 states selected to take part in an asphalt pavement density demonstration project for 2016.

The goal of that project is to show that an increase in in-place density can be achieved with minimal cost. A central component of the demonstration is not to change design minimums, but to build pavements as planned and then continue compaction to achieve better density.

Wisconsin participants seized the opportunity to add an air void regression component to the demonstration. WAPA member Mathy Construction built the pavement test sections on STH 21.

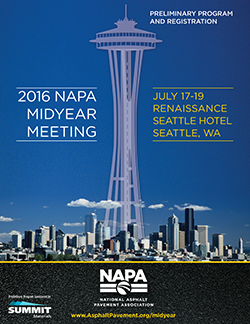

Section 1, the control section, was constructed with 4MT58-28S hot mix and 12.5mm (#4) Nmas aggregate with 3 rollers to achieve 4.0% air voids. A range of variables are under examination in the seven test sections:

As a follow up, WisDOT will be cutting cores to evaluate the level of compaction achieved and comparing results to the nuclear density data to validate which sections had the most impact on overall density of the mat.

We look forward to the test results, which may point the way to pavements that continue to exceed expectations for durability and performance.

Look for WAPA's 2016 Asphalt Pavement Design Guide later this year.

First, we have been hard at work in collaboration with our members on a major update to WAPA’s Asphalt Pavement Design Guide. This has been a top request among WAPA membership and cities and counties across the state, and we plan to publish this before the next Executive Update. Stay tuned.

Second, the Annual WAPA Conference will be here before you know it. We’re back in Madison on November 29 and 30, and we’ll have details to share soon. Please look for more information about our program and how to participate. We expect registration to open in October.

As always, please don’t hesitate to contact us if you have any questions or if there is ever any way we may be of assistance.

Thank you.