As we previewed in last month’s Executive Update, national research took center stage at the Transportation Research Board annual meeting in January and was prominently featured at the National Asphalt Pavement Association meeting as well.

We saw at both events that national research will continue to have a significant influence on the evolving state of practice in Wisconsin. The influence goes in the other direction too, with Wisconsin research results telling an important story nationally and helping shape practices elsewhere.

I’d like to start by turning over this Executive Update to WAPA’s Technical Director Deb Schwerman, who reported on the major takeaways from this year’s TRB meeting.

Something that jumped out at me right away was the excellent representation by the state of Wisconsin at the event. Even as 12,000 people from 70 nations came together at TRB, it seemed like I could never turn around without seeing a friendly face from back home: representatives from Wisconsin DOT, our asphalt industry—including several WAPA members—and Wisconsin research institutions. (We also convened at the annual Wisconsin reception that WAPA co-sponsored—always a very popular event.) It is rewarding to see our state demonstrating this kind of interest and leadership in national research.

WAPA members used the TRB meeting as an opportunity to share their innovations with an international audience. Product demonstrations by WAPA member Troxler showcased a system for continuous monitoring of asphalt plant aggregate blends to determine percent moisture, which is being assessed now in a Payne & Dolan facility. Troxler also displayed a nonnuclear density gauge whose prototype was demonstrated in Wisconsin by Northeast Asphalt.

I attended too many highly informative sessions in the formal TRB programming to cite them all in detail, but I will comment on two that were particularly noteworthy. (Feel free to contact me if you have any questions about these or any other developments at TRB.)

Presenters discussed the growing national trend toward performance based testing. As Dukatz discussed, what is really putting Wisconsin on the map in this area is how our state industry and DOT have partnered to pick the most promising tests and move forward in using them in trial specifications for pilot projects. Wisconsin has been using the Hamburg Wheel test (for deformation/rutting and moisture sensitivity), the Semicircular Bend test (for fatigue cracking), and the Disc-shaped Compact Tension test (for thermal cracking) in recent pilots. The agency-industry partnership in Wisconsin has never been closer as efforts continue to ensure that materials and pavements meet all performance requirements.

Another integral part of the pilot projects described by Dukatz was the increased use of recycled materials (reclaimed asphalt pavement and recycled asphalt shingles) to help fulfill WisDOT’s call to increase efficiencies and save money. The pilot projects pushed recycled content levels—and the associated performance tests—to their limits. The results of this work will be critical in tailoring Wisconsin’s standard specifications to meet local needs. WisDOT’s Barry Paye reported on these pilots in his 2014 WAPA Conference Presentation and wrote a forthcoming article in Roads and Bridges that will spotlight the work as well.

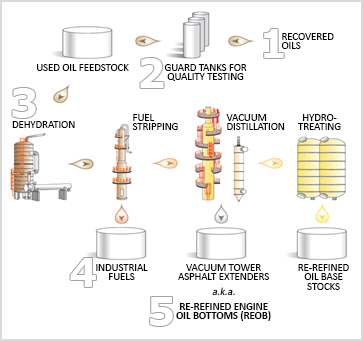

REOB are not widely used in Wisconsin, and we think a prudent course of action is to hold steady and wait while national research now in progress determines REOB’s impact on performance and establishes appropriate usage levels. Illinois, Iowa, Michigan and Minnesota do not allow REOB, so an explicit ban in Wisconsin is likely not necessary to keep it out. However, Wisconsin’s asphalt industry remains in open dialogue with WisDOT on this topic to ensure transparency and to keep all parties aware of any developments.

I also took advantage of my time at TRB to attend several standing committee meetings and join them as a friend:

- Standing Committee on Characteristics of Asphalt Materials

- Standing Committee on Characteristics of Asphalt Paving Mixtures to Meet Structural Requirements

- Standing Committee on Characteristics of Asphalt-Aggregate Combinations to Meet Surface Requirements

- Standing Committee on Characteristics of Nonasphalt Components of Asphalt Paving Mixtures

- Standing Committee on Flexible Pavement Construction and Rehabilitation

- Standing Committee on Flexible Pavement Design

My involvement will help keep Wisconsin plugged in to the latest research on a wide range of technical issues. I look forward to corresponding with the many personal contacts I made at these committee meetings and providing perspective on new developments.

Thanks again to Deb for lending her expertise and attention to national research at the TRB meeting.

NAPA’s January 2015 Research Project Summary provides an excellent snapshot of the research in progress. In the foreword, John Keating, Chairman of NAPA’s Marketing Council, describes the need: “Since [the inception of the Pavement Economics Committee] in 2012, 15 research and advocacy projects have been undertaken spanning six areas of competition—pavement design, pavement types election, legislative, quality and competitiveness, preservation, and sustainability. Through this research, the industry can continue to bring a superior product to market while addressing technical challenges and monitoring legislative advocacy needs.”

WAPA and other state asphalt pavement associations fund these projects as part of a pooled funding effort. The results of some NAPA research projects are more relevant to Wisconsin than others, but overall this is a great value for our association. Some projects that will make a difference here in Wisconsin include these projects:

- Develop an Industry Average Environmental Product Declaration (EPD). The expected outcome of this research is a real-time EPD software program that will allow asphalt mix producers to develop NAPA-certified EPDs for their various mixes in a fast, simple, and affordable manner. EPDs certified under this program will assist Wisconsin producers in demonstrating their commitment to sustainability. Dan Staebell with Mathy Construction is very involved in this effort, and the project ties closely with green rating systems like LEED and the International Green Construction Code.

- Effect of Speed of Construction on Total Costs for Maintenance, Rehabilitation and Reconstruction of Existing Pavements. One of the most recognized benefits of asphalt pavements is speed of construction, but this benefit is not always recognized in the pavement type selection process. The results of this project will quantify benefits of speed of construction, especially as related to pavement type selection and LCCA. This will be a valuable tool for the Wisconsin asphalt industry in helping present the business case for asphalt pavements.

- Targeted Education, Promotion, and Training Program. The training curriculum now in development will help educate Wisconsin city and county public works officials, as well as consulting engineers and engineering firms, on proper engineering methods required to design and deliver a high-quality asphalt pavement. The program will draw from best practices of all states, and it will also serve as a repository for Wisconsin practitioners to share their own best practices with others.

- Development of Thin Asphalt Overlay Mixes with High Recycle Content. Two major trends in asphalt pavement are pavements with high recycled content and thin overlays. This project ties these trends together, seeking to develop high binder (HBR) replacement surface mixes that have equivalent or better performance than standard mixes. The results of the testing and analysis will help provide guidelines that Wisconsin may be able to use for developing crack-resistant HBR surface mixes.

Wisconsin’s asphalt community is always looking for ways to do more with less. In light of funding uncertainties and shifting economic priorities, it is outstanding to see that innovators are exploring new techniques and practices that help stretch dollars and strengthen the economic case for asphalt by improving performance and longevity.

Like Deb, I am impressed by Wisconsin’s involvement on the national research scene. It helps ensure that our state’s transportation users are enjoying the latest improvements available.

I don’t think all the advances in our state would be possible without the close cooperation between industry and government, a thread that we’ve seen throughout this Executive Update and in past issues as well. The ties have never been stronger, and the partnership is helping everyone in our state achieve the common purpose of delivering a transportation system that is second to none.

Thank you.

Brandon Strand

Wisconsin Asphalt Pavement Association